Air Terminal: Complete Guide to Lightning Rod Systems

Quick Answer: An air terminal (also called a lightning rod) is a metal device installed at the highest point of a building to intercept lightning strikes and safely direct electrical current to the ground. Air terminals are required components of lightning protection systems per NFPA 780 and IEC 62305 standards. The most common types are Franklin rods (pointed), ESE terminals, and mesh conductor networks, typically made from copper, aluminum, or stainless steel.

What you'll learn in this guide:

- What an air terminal is and how it intercepts lightning strikes

- How air terminals work using the rolling sphere method and protection zones

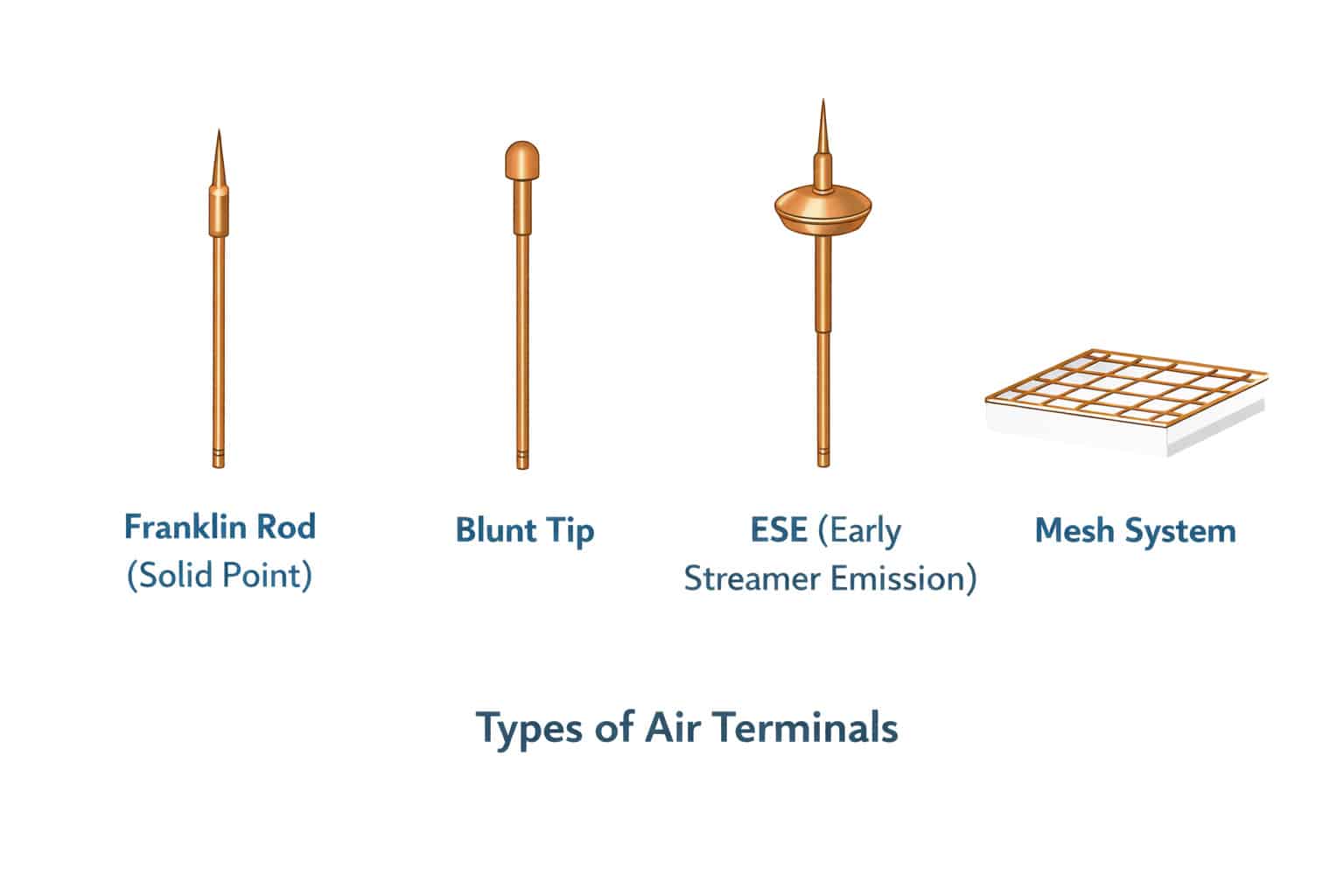

- 4 main types of air terminals: Franklin rod, Blunt tip, ESE, and Mesh systems

- Material comparison: Copper vs Aluminum vs Stainless Steel air terminals

- Applications across residential, commercial, industrial, and telecommunications facilities

- Installation requirements, lifespan, and maintenance guidelines

An air terminal serves as the critical entry point in a complete lightning protection system. According to NFPA 780 and IEC 62305 international standards, air terminals must be installed at the highest points of structures to provide preferential strike points for lightning. When integrated with down conductors and grounding electrode systems, air terminals create a safe pathway that protects buildings, equipment, and occupants from the destructive effects of lightning strikes reaching billions of volts and temperatures exceeding 30,000°C.

Common terminology: The terms "air terminal," "lightning rod," and "Franklin rod" all refer to the same device. "Air terminal" is the modern technical term used in engineering specifications, while "lightning rod" remains the popular term. Benjamin Franklin invented the first lightning rod in 1752, which is why they're sometimes called "Franklin rods."

What Is an Air Terminal and How Does It Protect Buildings?

Air Terminal Definition and Core Function

An air terminal (also called a lightning rod or air termination system) is a metal device installed at the highest point of a building or structure. According to international standards NFPA 780 and IEC 62305, an air terminal provides a preferential strike point for lightning, safely directing the electrical current through the lightning protection system to the ground.

Key physical characteristics of air terminals:

- Material: Copper, aluminum, or stainless steel for optimal conductivity

- Shape: Pointed or rounded metal rod designed for lightning interception

- Height: Typically 254mm to 600mm (10 to 24 inches) above the protected surface

- Location: Must be positioned higher than all objects requiring lightning protection

An air terminal cannot work alone. It must be integrated with down conductors and a proper grounding system to form a complete air termination network that effectively protects buildings from lightning strikes.

Air Terminal vs Lightning Rod vs Franklin Rod: Understanding the Terminology

| Term | Description | Usage Context |

|---|---|---|

| Air Terminal | Modern technical standard term for lightning rod systems | Engineering specifications, international standards (IEC 62305, NFPA 780) |

| Lightning Rod | Traditional common name for air terminal device | Daily communication, commercial product descriptions |

| Franklin Rod | Historical term named after inventor Benjamin Franklin (1752) | Historical literature and traditional lightning protection references |

All three terms refer to the same device with identical functions in a lightning protection system. This guide uses these terms interchangeably, with "air terminal" as the primary technical term.

Air Terminal Role in Complete Lightning Protection Systems

A complete lightning protection system (LPS) integrates air terminals with two other essential components:

1. Air Terminal (Strike Termination Device)

- Function: Intercepts direct lightning strikes at preferred points

- Location: Installed at highest points and vulnerable areas of buildings

- Common configurations: Single rods, multiple air terminals, or mesh conductor networks

2. Down Conductor System

- Function: Safely conducts lightning current from air terminals to ground

- Composition: Metal cables or copper strips connecting terminals to grounding electrodes

3. Grounding Electrode System

- Function: Dissipates lightning current safely into the earth

- Composition: Metal rods, plates, or copper ground ring buried underground

The air terminal serves as the critical "entry point" of the lightning protection system, the down conductor provides the "safe pathway," and the grounding system acts as the "discharge point." All three components must be properly bonded and installed according to lightning protection standards for effective building protection.

Figure 1: Complete lightning protection system with air terminal, down conductor, and grounding components

How Do Air Terminals Work to Intercept Lightning Strikes?

Lightning Interception Principle Behind Air Terminal Systems

Understanding lightning formation:

Lightning occurs when electrical charges accumulate in storm clouds. The cloud base develops negative charges, while ground objects develop positive charges through electromagnetic induction. When the voltage difference reaches millions of volts, an electrical discharge (lightning strike) occurs between cloud and ground.

How air terminals intercept lightning strikes:

- As a thunderstorm cloud approaches, a stepped leader (downward electrical channel) extends from the cloud toward the ground surface

- The air terminal's pointed tip generates a concentrated electric field and launches an upward streamer toward the descending leader

- When the upward and downward channels meet in mid-air, a conductive pathway forms

- Lightning current flows through the air terminal, down conductor, and into the grounding system

Why lightning preferentially strikes air terminals:

- Height advantage: Air terminals are positioned at the highest points, providing the shortest path to ground

- Superior conductivity: Metal construction conducts electricity far better than building materials

- Electric field enhancement: The pointed geometry of air terminal tips concentrates the electric field, facilitating upward streamer formation

Air Terminal Protection Zone and Rolling Sphere Method

Each air terminal creates a defined protection zone around its installation point. Objects and building areas within this zone receive protection from direct lightning strikes according to lightning protection standards.

Rolling Sphere Method for Air Terminal Placement:

The rolling sphere method (also called striking distance method) is the internationally recognized standard for determining air terminal protection zones per IEC 62305 and NFPA 780. Engineers visualize a sphere of a specific radius rolling over the building surface. Any area the sphere cannot touch (because it rests on air terminals or protected surfaces) is considered within the lightning protection zone.

| Lightning Protection Level | Rolling Sphere Radius | Typical Air Terminal Applications |

|---|---|---|

| Class I (LPL I) | 20m (66 ft) | High-risk facilities: explosives storage, ammunition depots, critical infrastructure |

| Class II (LPL II) | 30m (98 ft) | Important commercial buildings, data centers, hospitals |

| Class III (LPL III) | 45m (148 ft) | General industrial facilities, warehouses, manufacturing plants |

| Class IV (LPL IV) | 60m (197 ft) | Ordinary residential and commercial buildings |

The height and placement of air terminals directly determine the size of the lightning protection zone. Larger buildings typically require multiple air terminals or a mesh conductor network to achieve complete lightning protection coverage according to the rolling sphere method calculations.

Figure 2: Rolling sphere method for determining air terminal protection zones according to IEC 62305

Types of Air Terminals for Lightning Protection

Franklin Rod Air Terminal (Solid Point Design)

The Franklin rod air terminal is the most widely used and globally accepted type of lightning rod, featuring a sharp pointed tip for optimal lightning interception.

Key characteristics of Franklin rod air terminals:

- Design: Solid metal rod with conical or needle-shaped pointed tip

- Proven history: Invented by Benjamin Franklin in 1752, providing reliable lightning protection for over 270 years

- Universal standard recognition: Accepted by NFPA 780, IEC 62305, UL 96A, and all major international lightning protection standards

Ideal applications: Franklin rod air terminals are suitable for residential buildings, commercial structures, industrial facilities, and all general-purpose lightning protection applications.

Franklin rods remain the most widely specified air terminal type globally due to proven reliability, universal code acceptance, and cost-effectiveness for lightning protection systems.

Blunt Tip Air Terminal

Blunt tip air terminals feature a rounded or hemispherical end instead of a sharp point, representing an alternative design philosophy in lightning protection.

Key characteristics of blunt tip air terminals:

- Design: Rounded tip geometry instead of pointed end

- Technical theory: Some research suggests blunt tips may reduce localized thermal damage at the lightning strike point

- Acceptance status: Still debated in academic circles; most international standards continue to favor traditional pointed air terminal designs

Ideal applications: Specialized projects with specific requirements for blunt tip air terminal configurations.

Early Streamer Emission (ESE) Air Terminal

ESE air terminals (Early Streamer Emission devices) incorporate electronic components that manufacturers claim emit upward streamers earlier than conventional air terminals, theoretically extending the protection radius.

Key characteristics of ESE air terminals:

- Design: Built-in electronic trigger or discharge device within the air terminal housing

- Manufacturer claims: Protection radius allegedly 2-4 times larger than standard Franklin rod air terminals

International standard recognition of ESE air terminals:

| Standard/Region | ESE Air Terminal Recognition Status |

|---|---|

| France NF C 17-102 | ✅ Recognized and regulated |

| Spain UNE 21186 | ✅ Recognized and regulated |

| USA NFPA 780 | ❌ Not recognized or approved |

| International IEC 62305 | ❌ Not recognized or approved |

Ideal applications: Large open areas in France, Spain, and other regions where ESE air terminal standards are officially recognized.

Mesh System Air Termination Network

A mesh system air termination network uses a grid of horizontal conductors across the roof surface instead of individual vertical air terminal rods, providing distributed lightning strike points.

Key characteristics of mesh air termination systems:

- Design: Horizontal conductor grid covering the entire roof area

- Lightning protection principle: Multiple potential strike points distribute lightning risk across the air termination network

- Grid spacing: Typically 5m × 5m to 20m × 20m mesh size depending on lightning protection level requirements

Advantages of mesh air termination systems:

- Complete, uniform lightning protection coverage with no gaps in the protection zone

- Can be concealed beneath roofing materials for aesthetic considerations

- Eliminates visible air terminal rods for architecturally sensitive projects

Ideal applications: Flat roof buildings, large industrial warehouses, solar photovoltaic farms, and structures requiring comprehensive air terminal coverage.

Air Terminal Type Comparison

| Air Terminal Type | Design Features | Global Standard Acceptance | Cost Range | Best Use Cases |

|---|---|---|---|---|

| Franklin Rod | Pointed rod air terminal | ⭐⭐⭐⭐⭐ Universal | $ Low | General buildings and lightning protection applications |

| Blunt Tip | Rounded rod air terminal | ⭐⭐⭐⭐ High | $ Low | Specific project requirements |

| ESE | Active electronic air terminal | ⭐⭐⭐ Regional | $$$ High | Large open areas in approved regions |

| Mesh Network | Horizontal conductor grid | ⭐⭐⭐⭐⭐ Universal | $$ Medium | Flat roofs and comprehensive coverage needs |

Figure 3: Four main types of air terminal systems - Franklin Rod, Blunt Tip, ESE, and Mesh Network

Air Terminal Materials: Copper, Aluminum, and Stainless Steel

Copper Air Terminals

Copper air terminals are the most recommended material choice for professional lightning protection systems due to superior electrical and physical properties.

Characteristics of copper air terminals:

- Electrical conductivity: Excellent - highest among common air terminal materials (100% IACS reference standard)

- Corrosion resistance: Excellent performance in coastal, industrial, and all environmental conditions

- Service lifespan: 50+ years with minimal maintenance for copper air terminal systems

- Material cost: Higher initial investment than aluminum air terminals

TrilPeak copper air terminals: Manufactured from 99.9% pure copper meeting UL 96A material standards, available in custom lengths and configurations for all lightning protection applications.

Ideal applications: Coastal environments, industrial facilities with corrosive atmospheres, high-standard lightning protection projects, and long-term infrastructure investments requiring reliable air terminal performance.

Aluminum Air Terminals

Aluminum air terminals provide a lightweight and economical alternative to copper for many lightning protection applications.

Characteristics of aluminum air terminals:

- Electrical conductivity: Good - approximately 61% of copper air terminal conductivity

- Weight advantage: 70% lighter than copper air terminals, reducing structural load

- Corrosion resistance: Good performance in dry inland environments; poor performance in coastal salt-spray conditions

- Service lifespan: 30-40 years for aluminum air terminal installations

- Material cost: 30-50% lower than copper air terminals

Ideal applications: Inland areas with low humidity, budget-constrained lightning protection projects, and large-scale air terminal installations where weight reduction is beneficial.

Stainless Steel Air Terminals

Stainless steel air terminals offer superior mechanical strength and aesthetic appearance for specialized lightning protection applications.

Characteristics of stainless steel air terminals:

- Electrical conductivity: Lower than copper and aluminum - approximately 2.4% of copper conductivity

- Mechanical strength: Highest tensile and impact resistance among air terminal materials

- Corrosion resistance: Excellent performance in all environmental conditions

- Aesthetic appearance: Attractive polished silver finish for visible air terminal installations

Due to lower electrical conductivity, stainless steel air terminals typically require larger cross-sectional areas to meet lightning current-carrying capacity requirements per international standards.

Ideal applications: Architectural projects with high aesthetic standards, corrosive industrial environments, and applications requiring maximum air terminal durability.

Air Terminal Material Comparison

| Air Terminal Material | Electrical Conductivity | Corrosion Resistance | Expected Lifespan | Material Cost |

|---|---|---|---|---|

| Copper | ⭐⭐⭐⭐⭐ Excellent | ⭐⭐⭐⭐⭐ Excellent | 50+ years | High |

| Aluminum | ⭐⭐⭐⭐ Good | ⭐⭐⭐ Good (inland only) | 30-40 years | Low |

| Stainless Steel | ⭐⭐ Fair | ⭐⭐⭐⭐⭐ Excellent | 40+ years | Medium |

Air terminal material selection guidance:

- Choose copper air terminals: Most professional applications, coastal and industrial environments, projects requiring maximum reliability

- Choose aluminum air terminals: Inland locations, budget-limited projects, large installations where weight matters

- Choose stainless steel air terminals: Architecturally sensitive projects with high aesthetic requirements

Figure 4: Comparison of air terminal materials - Copper, Aluminum, and Stainless Steel

Air Terminal Applications Across Industries

Residential Building Air Terminal Systems

Typical residential air terminal configuration:

- Number of air terminals: 2-6 units depending on house size, roof complexity, and protection zone calculations

- Installation locations: Roof ridge lines, chimneys, gable ends, and roof corners

- Material selection: Aluminum or copper air terminals based on budget and environmental conditions

Lightning protection goals: Personal safety for occupants, fire prevention from lightning strikes, and protection of household electrical systems and appliances.

Commercial and Industrial Facility Air Terminals

Typical commercial/industrial air terminal configuration:

- Multiple individual air terminals or complete mesh conductor networks for large roof areas

- Material selection: Primarily copper air terminals for maximum reliability and longevity

- Integration with building management systems and lightning monitoring equipment

Lightning protection goals: Critical equipment protection, business continuity assurance, employee safety, and insurance premium reduction.

Common applications: Manufacturing plants, warehouses and distribution centers, shopping malls, office buildings, and educational facilities.

Telecommunications Tower and Data Center Air Terminals

Lightning protection challenges: Telecommunications towers present extremely high lightning strike risk due to height and exposed locations. Data centers house sensitive electronic equipment vulnerable to lightning-induced surges.

Typical air terminal system configuration:

- Tower-mounted air terminals at the highest point with multi-layer grounding electrode systems

- High lightning protection level classification (typically Class I or Class II per IEC 62305)

- Comprehensive integration with surge protection devices (SPD) on all power and data circuits

Lightning protection goals: Server and network equipment protection, continuous uptime maintenance, and prevention of data loss from lightning-related power disturbances.

Oil, Gas, and Chemical Facility Air Terminals

Lightning risks: Petroleum and chemical facilities contain flammable and explosive materials where lightning strikes can trigger catastrophic fires or explosions.

Air terminal system requirements:

- Enhanced lightning protection levels beyond standard building requirements

- Explosion-proof and intrinsically safe air terminal components and connections

- More frequent inspection intervals and rigorous maintenance protocols for all lightning protection equipment

Lightning protection goals: Storage tank and pipeline protection, control room and critical infrastructure safety, and prevention of ignition sources in hazardous classified areas.

Solar Farm and Wind Turbine Air Terminal Systems

Lightning protection challenges: Renewable energy installations occupy large open areas with equipment continuously exposed to weather conditions, making them prime targets for lightning strikes.

Solar photovoltaic farm air terminals:

- Mesh conductor networks or strategically placed air terminal rods covering photovoltaic arrays

- Surge protection devices on both DC solar circuits and AC grid interconnection equipment

Wind turbine lightning protection:

- Built-in air terminal receptors integrated into blade tips and nacelle housing

- Tower structure serves as down conductor pathway to foundation grounding system

Frequently Asked Questions About Air Terminals

What is the difference between an air terminal and a lightning rod?

Air terminal and lightning rod refer to exactly the same lightning protection device. "Air terminal" is the modern technical term used in international engineering standards like NFPA 780 and IEC 62305. "Lightning rod" is the traditional common name that most people recognize. "Franklin rod" is the historical term honoring inventor Benjamin Franklin. All three terms describe identical devices that intercept lightning strikes and direct current safely to the grounding system.

Do air terminals attract lightning to buildings?

No, air terminals do not "attract" additional lightning strikes to a building. Whether lightning strikes a particular location depends entirely on storm cloud electrical conditions and ground topography, not on the presence of air terminal systems.

The air terminal's critical function is to provide a controlled, safe strike point when a lightning discharge is already targeting the vicinity. By offering the path of least resistance, air terminals ensure lightning current flows through engineered conductors to ground rather than through building structure, wiring, or occupants.

How many air terminals does my building need for complete lightning protection?

The required number of air terminals depends on building dimensions, roof geometry, and lightning protection level requirements:

- Small residential buildings: Typically 2-4 air terminals for complete coverage

- Medium commercial buildings: Generally 6-12 air terminals depending on roof area

- Large industrial facilities: May require dozens of individual air terminals or a complete mesh conductor network

Each air terminal creates a limited protection zone calculated using the rolling sphere method. All roof protrusions including chimneys, antennas, HVAC equipment, and skylights must fall within protected zones. Professional lightning protection system design per NFPA 780 or IEC 62305 standards is strongly recommended for accurate air terminal placement and quantity determination.

What is the minimum height requirement for air terminals?

According to NFPA 780 lightning protection standards, the minimum air terminal height is 254mm (10 inches) above the surface being protected. Standard commercial air terminal products typically range from 254mm to 600mm (10 to 24 inches) in length.

The critical design requirement is that air terminals must extend above all objects requiring lightning protection. For buildings with tall roof protrusions like communication antennas or equipment enclosures, taller air terminal rods or elevated mounting bases may be necessary to maintain proper protection zone coverage per rolling sphere method calculations.

Can I install air terminals myself or should I hire a professional?

Self-installation of air terminal lightning protection systems is strongly discouraged for multiple important reasons:

- Safety concerns: Working at roof heights presents serious fall hazards requiring proper safety equipment and training

- Technical complexity: Proper protection zone calculations, bonding techniques, and grounding system integration require specialized knowledge

- System effectiveness: Incorrect air terminal placement, inadequate connections, or improper grounding can result in complete lightning protection system failure

- Insurance requirements: Many property insurance policies require professional installation certification and may deny lightning damage claims for non-compliant systems

Hiring a certified lightning protection professional who follows NFPA 780 or IEC 62305 standards is strongly recommended for safe, effective air terminal system installation.

Which material is best for air terminals - copper, aluminum, or stainless steel?

Copper air terminals are the most universally recommended material choice because they offer:

- Superior electrical conductivity for maximum lightning current-carrying capacity

- Excellent corrosion resistance in all environmental conditions including coastal and industrial atmospheres

- Longest service lifespan exceeding 50 years with minimal maintenance

Alternative air terminal materials for specific situations:

- Aluminum air terminals: Appropriate for inland dry environments and budget-constrained projects where lower initial cost is a priority

- Stainless steel air terminals: Best for architecturally sensitive projects where aesthetic appearance is critical

Air terminal material selection should consider environmental corrosion factors (coastal salt exposure, industrial pollution), project budget constraints, and required service life expectations.

Do I still need surge protectors if I have air terminals installed?

Yes, absolutely. Air terminals and surge protection devices (SPD) defend against different lightning-related threats and both are essential components of comprehensive building protection:

- Air terminals (external lightning protection): Protect building structure from direct lightning strikes by safely conducting current to ground

- Surge protection devices (internal lightning protection): Protect sensitive electrical equipment from induced voltage surges and transients entering through power lines, data cables, and telecommunications circuits

A complete lightning protection system per IEC 62305 requires both external protection (air terminals + down conductors + grounding electrodes) and internal protection (surge protection devices + equipotential bonding of all metallic systems).

What is the expected lifespan of air terminal systems?

Air terminal service life varies significantly based on material selection:

| Air Terminal Material | Expected Lifespan |

|---|---|

| Copper air terminals | 50+ years |

| Aluminum air terminals | 30-40 years |

| Stainless steel air terminals | 40+ years |

Factors significantly affecting air terminal lifespan include environmental conditions (coastal salt spray accelerates corrosion, industrial pollution can degrade materials), physical damage from severe weather or impacts, and quality of regular inspection and maintenance. Annual professional inspections can identify developing issues early and substantially extend air terminal system service life.

What damage can occur if a building is struck by lightning without air terminal protection?

Lightning strikes on unprotected buildings can cause catastrophic damage:

- Structural damage: Lightning current seeking paths to ground can explosively damage building materials. Moisture in concrete, masonry, or wood can instantly vaporize, causing violent cracking, spalling, and structural failure

- Fire ignition: Lightning channel temperatures exceeding 30,000°C (54,000°F) - five times hotter than the sun's surface - can instantly ignite combustible roofing materials, insulation, and structural components

- Electrical system destruction: Massive voltage surges propagate through electrical wiring, destroying all connected equipment including HVAC systems, appliances, computers, and telecommunications equipment

- Personal injury and fatality: Direct lightning current or side flash discharges can cause severe injuries or death to building occupants

Proper air terminal lightning protection systems eliminate these risks by providing a controlled, safe pathway for lightning current that bypasses building structure and electrical systems entirely.

Are ESE air terminals superior to traditional Franklin rod air terminals?

This remains a controversial technical debate in the lightning protection industry with differing perspectives:

ESE air terminal manufacturers claim:

- Protection radius coverage 2-4 times larger than traditional Franklin rod air terminals

- Fewer air terminal units required for equivalent protection zone coverage, reducing installation costs

- Official recognition by French NF C 17-102 and Spanish UNE 21186 national standards

Independent experts and major standards organizations counter:

- ESE air terminals are explicitly not recognized by US NFPA 780 standards

- ESE technology is not accepted by international IEC 62305 standards

- Claimed performance advantages in natural lightning strike conditions have not been independently verified through rigorous field testing

- ESE air terminal costs are 3-5 times higher than Franklin rod systems

Practical conclusion: Franklin rod air terminals have delivered proven, reliable lightning protection for over 270 years and maintain universal recognition by all major international standards. ESE air terminals are accepted in certain specific regions, but selection must carefully consider applicable local code requirements, independent testing data availability, and project budget constraints.

Conclusion: Selecting the Right Air Terminal System

The air terminal serves as the critical first component of any effective lightning protection system. When selecting air terminals for your project, carefully consider building type and height, local environmental conditions including corrosion factors, applicable lightning protection standards (NFPA 780 or IEC 62305), and overall budget constraints.

Key air terminal selection guidelines:

- Material choice: Copper air terminals are the most recommended option for the majority of professional lightning protection applications due to superior conductivity, corrosion resistance, and longevity

- Type selection: Franklin rod air terminals remain the most reliable, universally accepted, and cost-effective lightning rod type with over 270 years of proven field performance

- System integration: Air terminals must be properly integrated with down conductors, grounding electrode systems, and surge protection devices to create complete, effective lightning protection per international standards

For detailed technical specifications, product information, or project-specific air terminal system design assistance, explore our complete lightning protection system solutions or contact the TrilPeak engineering team directly.

Related Lightning Protection Resources

- What is a Lightning Protection System? Complete Technical Guide

- Lightning Arrester vs Surge Arrester: Key Differences Explained

- Lightning Protection System Products and Solutions

References and Standards

- NFPA 780: Standard for the Installation of Lightning Protection Systems. National Fire Protection Association. https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=780

- IEC 62305: Protection Against Lightning (Parts 1-4). International Electrotechnical Commission. https://webstore.iec.ch/publication/6793

- UL 96A: Installation Requirements for Lightning Protection Systems. Underwriters Laboratories.

- Lightning Protection Institute (LPI). Design Guide for Lightning Protection Systems. https://www.lightning.org/