Type 1 vs Type 2 vs Type 3 SPD: What Are the Key Differences?

Type 1 vs Type 2 vs Type 3 SPD are three surge protection device classifications defined in IEC 61643-11. Understanding the key differences between Type 1, Type 2, and Type 3 SPD is essential for proper electrical system protection. This comprehensive guide compares Type 1 vs Type 2 vs Type 3 SPD across test waveforms, discharge currents, installation locations, and cascade protection coordination.

Choosing the right SPD type Type 1 vs Type 2 vs Type 3 SPD is critical for safeguarding electrical systems against lightning strikes and power surges. According to IEC 61643-11 standards and NEC Article 230.67, surge protective devices are classified into three types—Type 1 SPD, Type 2 SPD, and Type 3 SPD—based on their protection capabilities, test waveforms, and installation locations. Understanding the technical differences between Type 1 vs Type 2 vs Type 3 SPD ensures optimal cascade protection coordination and compliance with international electrical codes.

This comprehensive Type 1 vs Type 2 vs Type 3 SPD comparison guide analyzes these surge protective device classifications across key technical dimensions—test waveforms, discharge current capacity, voltage protection levels (Up), installation requirements, and application scenarios—to help electrical engineers and facility managers make informed surge protection selection decisions.

Quick Answer:

Type 1 SPD: Service entrance protection against direct lightning (10/350μs, 25-100kA)

Type 2 SPD: Distribution panel protection against switching surges (8/20μs, 20-100kA)

Type 3 SPD: Point-of-use protection for equipment (8/20μs, 5-10kA, requires upstream Type 2)

| Comparison Factor | Type 1 SPD (Class I) |

Type 2 SPD (Class II) |

Type 3 SPD (Class III) |

|---|---|---|---|

| Test Waveform | 10/350μs | 8/20μs | 8/20μs |

| Discharge Current | Iimp = 25-100kA (Impulse current) |

In = 10-40kA Imax = 20-100kA (Nominal/Max current) |

Imax = 5-10kA (Max discharge current) |

| Energy Handling | 50,000+ J/phase | 2,000-15,000 J/phase | 200-1,000 J/phase |

| Voltage Protection Level (Up) | ≤ 4.0 kV (400V systems) | ≤ 2.5 kV | ≤ 1.5 kV |

| Installation Location | Service entrance (main panel) | Distribution panels | Final outlet / equipment |

| Protection Type | Direct lightning strikes | Switching surges + indirect lightning | Local equipment protection |

| Cascade Requirement | Standalone or with Type 2/3 | After Type 1 (if present) or standalone | Must be used with upstream Type 2 |

| IEC 61643-11 Classification | Class I Test | Class II Test | Class III Test |

Cascade Coordination Rule: Maintain a minimum 10-meter cable distance between Type 1 → Type 2 → Type 3 SPD stages for proper energy coordination per IEC 61643-11. Type 3 SPD must never be used standalone.

Type 1 vs Type 2 vs Type 3 SPD: Official Definitions per IEC 61643-11

Official SPD Type Definitions

- Type 1 SPD Definition: Surge protective devices designed to withstand direct lightning surge current (Iimp) with 10/350µs impulse waveform. Installed at service entrance per IEC 61643-11 Class I testing requirements.

- Type 2 SPD Definition: Surge protective devices rated for induced lightning surges and switching transients (In/Imax) with 8/20µs waveform. Installed at distribution panels per IEC 61643-11 Class II requirements.

- Type 3 SPD Definition: Surge protective devices for residual surge protection (Imax) with 8/20µs combination wave. Installed at point-of-use near sensitive equipment per IEC 61643-11 Class III requirements.

These Type 1 vs Type 2 vs Type 3 SPD definitions are critical for proper SPD selection and cascade protection system design per IEC 61643-11 standards.

Understanding Type 1 vs Type 2 vs Type 3 SPD Classifications

Understanding the distinctions between Type 1 vs Type 2 vs Type 3 SPD is essential for proper surge protection system design. Each SPD type serves a specific role in protecting electrical systems: Type 1 SPD handles direct lightning at service entrance, Type 2 SPD manages distribution-level surges, and Type 3 SPD provides point-of-use protection. This Type 1 vs Type 2 vs Type 3 SPD classification system, defined by IEC 61643-11, ensures coordinated protection through proper cascade configuration.

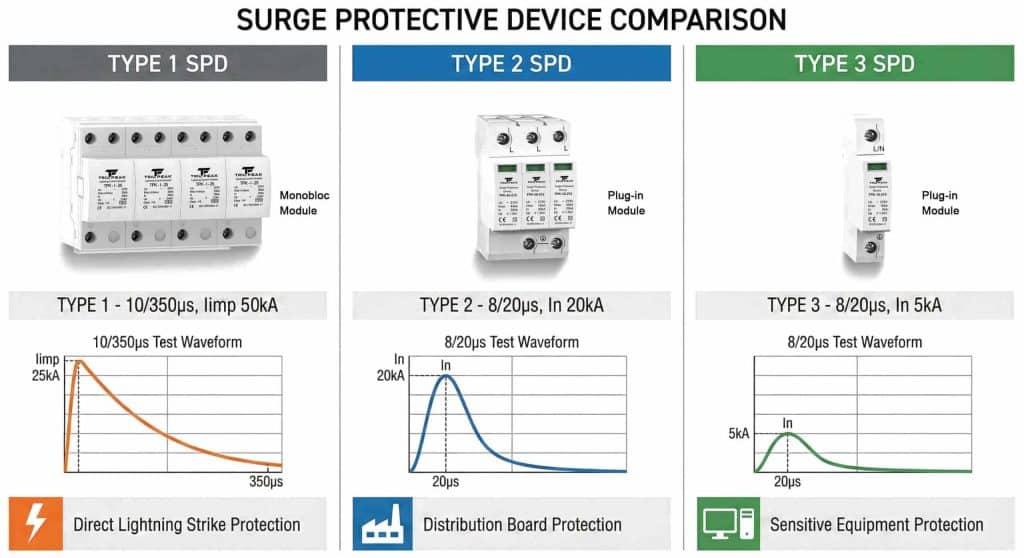

Figure 1: Type 1 vs Type 2 vs Type 3 SPD Comparison Chart

What is Type 1 SPD?

Type 1 SPD (IEC 61643-11 Class I) provides the highest level of surge protection against direct lightning strikes at the service entrance. Type 1 surge protective devices are designed to handle the massive energy from a 10/350μs current waveform, which simulates direct lightning current flowing through the electrical system. According to NEC 230.67, Type 1 SPD installation is mandatory for buildings with overhead power lines exposed to lightning.

Key Characteristics of Type 1 SPD:

- Test Waveform: 10/350μs impulse current (Iimp)

- Discharge Current: 25kA to 100kA per phase

- Energy Handling: Very high (50,000+ joules)

- Voltage Protection Level (Up): ≤4.0kV (for 400V systems)

- Installation: Main service entrance, before or after the main disconnect

Typical Applications for Type 1 SPD: Industrial facilities with overhead power lines, buildings with lightning protection systems (LPS), utility transformer secondary terminals, critical infrastructure requiring maximum protection.

What is Type 2 SPD?

Type 2 SPD (IEC 61643-11 Class II) protects against switching transients and indirect lightning at distribution panel locations. Type 2 surge protective devices are tested with the 8/20μs waveform and rated by maximum discharge current (Imax) capacity, typically ranging from 20kA to 100kA per phase. Type 2 SPD represents the most widely installed surge protection type for general facility protection and is commonly used in cascade protection systems downstream from Type 1 SPD.

Key Characteristics of Type 2 SPD:

- Test Waveform: 8/20μs impulse current

- Discharge Current: In = 10-40kA, Imax = 20-100kA

- Energy Handling: Medium (2,000-15,000 joules)

- Voltage Protection Level (Up): ≤2.5kV (for 400V systems)

- Installation: Distribution panels, sub-panels, equipment distribution boards

Typical Applications for Type 2 SPD: Commercial buildings with underground cable supply, secondary distribution boards, UPS input protection, branch circuit protection in office buildings, second level in cascade protection with Type 1 SPD.

What is Type 3 SPD?

Type 3 SPD (IEC 61643-11 Class III) provides point-of-use protection for sensitive electronic equipment at final connection points. Type 3 surge protective devices are designed to suppress low-energy residual surges that reach end-use devices, but must always be used in combination with upstream Type 2 SPD in proper cascade protection configuration. Per IEC 61643-11, Type 3 SPD cannot be used as standalone protection.

Key Characteristics of Type 3 SPD:

- Test Waveform: 8/20μs combination wave

- Discharge Current: Imax = 5-10kA

- Energy Handling: Low (200-1,000 joules)

- Voltage Protection Level (Up): ≤1.5kV (for 230V systems)

- Installation: Wall outlets, plug-in strips, equipment terminals

Typical Applications for Type 3 SPD: Medical devices, laboratory instruments, server rack PDUs, precision manufacturing equipment, telecommunications systems, completing three-level cascade protection systems.

Important: Type 3 SPD cannot be used alone per IEC 61643-11 requirements. It requires upstream Type 2 SPD protection in cascade coordination to prevent overload damage from high-energy surges.

Type 1 vs Type 2 vs Type 3 SPD: In-Depth Technical Comparison

The following Type 1 vs Type 2 vs Type 3 SPD technical comparison examines five critical dimensions that determine surge protective device selection and cascade protection effectiveness.

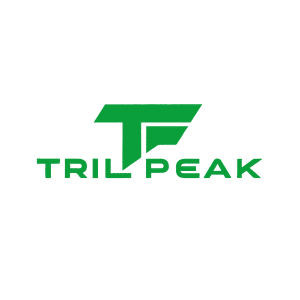

1. Type 1 vs Type 2 vs Type 3 SPD Test Waveform Differences: 10/350μs vs 8/20μs

The test waveform defines the type and severity of surge energy each SPD classification must withstand per IEC 61643-11 standards. This is the most fundamental technical distinction between Type 1, Type 2, and Type 3 SPD.

Figure 2: 10/350μs vs 8/20μs Lightning Impulse Waveform Comparison

| Parameter | Type 1 SPD (10/350μs) | Type 2 & Type 3 SPD (8/20μs) |

|---|---|---|

| Waveform Description | 10μs rise time, 350μs decay to 50% | 8μs rise time, 20μs decay to 50% |

| Energy Level | Very high (direct lightning) | Medium to low (indirect/attenuated) |

| Surge Origin | Direct lightning strikes | Switching operations, nearby lightning |

| Duration | Longer (350μs half-value time) | Shorter (20μs half-value time) |

Why This Matters for SPD Selection:

- Type 1 SPD must withstand sustained high-energy surges from direct lightning, requiring larger varistors and robust internal components per 10/350μs test requirements

- Type 2/3 SPD handle shorter-duration surges with less total energy per 8/20μs test standard, allowing more compact designs

- The 10/350μs waveform carries significantly more energy than 8/20μs at the same peak current—this is why Type 1 SPD is physically larger and more expensive

Selection Tip: Buildings with overhead power lines exposed to direct lightning must use Type 1 SPD at the service entrance per NEC 230.67. Underground cable supplies typically only require Type 2 SPD unless direct lightning exposure exists.

2. Type 1 vs Type 2 vs Type 3 SPD Discharge Current Ratings: Iimp vs Imax vs In

SPD discharge current ratings determine how much surge energy the device can safely divert to ground. Type 1, Type 2, and Type 3 SPD use different current parameters based on their IEC 61643-11 classification.

| SPD Type | Current Parameter | Typical Range | Meaning |

|---|---|---|---|

| Type 1 SPD | Iimp (Impulse Current) | 25kA - 100kA | Maximum 10/350μs current the SPD can discharge |

| Type 2 SPD | In (Nominal Discharge) Imax (Maximum Discharge) |

In: 10-40kA Imax: 20-100kA |

In: Rated 8/20μs discharge current Imax: Maximum single-impulse capacity |

| Type 3 SPD | Imax (Maximum Discharge) | 5kA - 10kA | Maximum 8/20μs combination wave current |

Key Differences Explained:

- Type 1 SPD: Must handle direct lightning current (Iimp), representing the most severe surge condition per IEC 61643-11 Class I testing

- Type 2 SPD: Rated by both nominal current In (regular operation) and maximum current Imax (occasional extreme surges) for cascade protection coordination

- Type 3 SPD: Handles only residual surges after upstream attenuation in cascade systems, requiring much lower capacity

Selection Tip: For high-exposure installations (tall buildings, industrial sites), select Type 1 SPD with Iimp ≥ 50kA per phase. For Type 2 SPD in cascade protection, choose In between 20-40kA based on downstream equipment value.

3. Type 1 vs Type 2 vs Type 3 SPD Voltage Protection Level (Up) Comparison

The Voltage Protection Level (Up) is the maximum voltage let-through that appears across SPD terminals during a surge event. Proper Up coordination between Type 1, Type 2, and Type 3 SPD is essential for effective cascade protection per IEC 61643-11 requirements.

| SPD Type | Voltage Protection Level (Up) | Protected Equipment Impulse Withstand |

|---|---|---|

| Type 1 SPD | ≤4.0kV (400V systems) | ≥6kV (Category III equipment) |

| Type 2 SPD | ≤2.5kV (400V systems) | ≥4kV (Category II equipment) |

| Type 3 SPD | ≤1.5kV (230V systems) | ≥2.5kV (Category I sensitive electronics) |

Why Cascade Protection Coordination Matters:

Proper SPD coordination requires each downstream device to have progressively lower Up values. This creates a "protection cascade" where:

- Type 1 SPD clamps the incoming surge to ~4kV at service entrance

- Type 2 SPD further reduces it to ~2.5kV at distribution panels

- Type 3 SPD provides final protection at ~1.5kV for sensitive equipment

Warning: If Type 3 SPD has a higher Up than Type 2 SPD, it will not activate during surges, making cascade protection ineffective. Always verify Up coordination in multi-stage surge protection designs.

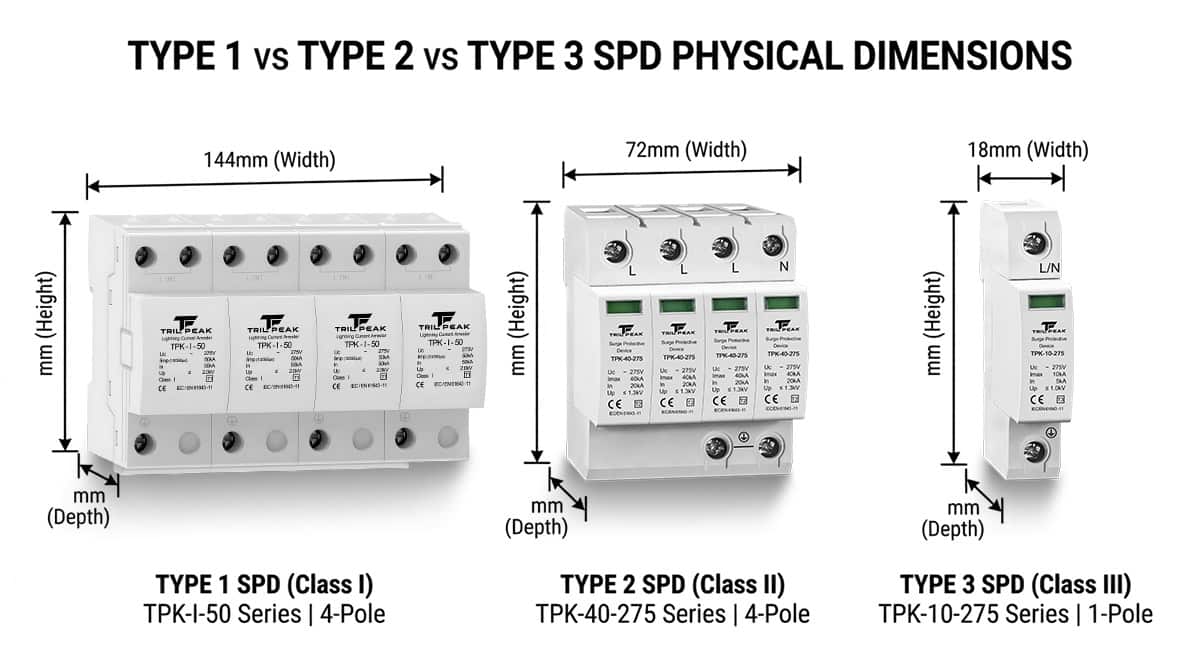

Physical Dimensions and Installation Space Requirements

Understanding the physical size differences between Type 1, Type 2, and Type 3 SPD is essential for DIN rail installation planning and panel space allocation.

Figure 3: Type 1 vs Type 2 vs Type 3 SPD Physical Dimensions Comparison

As shown in Figure 3, Type 1 SPD requires significantly more panel space due to its high-energy handling components. Typical dimensions:

- Type 1 SPD: 144mm W × 64mm H × 50mm D (4-pole configuration)

- Type 2 SPD: 72mm W × 90mm H × 68mm D (4-pole modular design)

- Type 3 SPD: 18mm W × 90mm H × 60mm D (1-pole compact design)

4. SPD Installation Location and Cascade Distance Requirements

Each SPD type has specific installation requirements based on electrical system architecture and the need for energy coordination between cascade protection stages per IEC 61643-11.

Figure 4: SPD Installation Locations and Cascade Distance Requirements

| SPD Type | Installation Location | Minimum Distance to Next Stage |

|---|---|---|

| Type 1 SPD | Service entrance main panel (before or after main disconnect) | ≥10 meters cable length to Type 2 |

| Type 2 SPD | Distribution boards, sub-panels, equipment panels | ≥10 meters cable length to Type 3 |

| Type 3 SPD | Point of use: wall outlets, equipment terminals, plug strips | N/A (final stage) |

Why 10-Meter Minimum Distance for Cascade Protection?

The cable between cascaded SPDs acts as a decoupling inductor, creating impedance that:

- Ensures upstream SPD activates first during major surges in cascade coordination

- Prevents simultaneous activation that could overload downstream SPD

- Allows proper energy sharing between Type 1, Type 2, and Type 3 protection stages

Design Tip: If physical distance < 10 meters in cascade protection systems, install a decoupling choke (30-60μH inductance) between SPD stages to achieve proper energy coordination per IEC 61643-11.

5. Application Scenarios and Code Compliance for SPD Types

Understanding when to use Type 1 vs Type 2 vs Type 3 SPD depends on electrical system configuration and building type. Different installations have specific surge protective device requirements based on exposure risk and applicable electrical codes including NEC 230.67 and IEC 61643-11.

When to Use Type 1 SPD:

- Overhead power lines: Buildings supplied by aerial conductors exposed to direct lightning (NEC 230.67 requirement)

- Lightning Protection Systems (LPS): Structures with air terminals and down conductors per IEC 62305

- Industrial facilities: High-value equipment or continuous process operations requiring maximum surge protection

- Critical infrastructure: Hospitals, data centers, emergency services requiring cascade protection systems

When to Use Type 2 SPD:

- Underground cable supply: Buildings with low direct lightning exposure per IEC 61643-11

- Distribution panels: Secondary boards feeding multiple branch circuits in cascade coordination

- Equipment protection: UPS systems, HVAC controllers, elevator panels requiring surge protection

- Residential properties: When Type 1 SPD is not mandated by local electrical code

When to Use Type 3 SPD:

- Sensitive electronics: Medical devices, laboratory instruments, telecommunications requiring point-of-use protection

- IT equipment: Server racks, network switches, storage arrays in cascade protection systems

- Precision manufacturing: CNC machines, automated test equipment requiring low residual voltage

- Always in combination with Type 2 SPD—never as standalone protection per IEC 61643-11

| Standard | Key Requirement |

|---|---|

| NEC Article 230.67 | Mandatory SPD at service entrance for all dwelling units (effective 2020) |

| IEC 61643-11 | Defines Type 1/2/3 SPD classification and test methods |

| IEEE C62.41 | Categorizes surge environments (A, B, C locations) |

| UL 1449 4th Edition | Requires Measured Limiting Voltage (MLV) testing and Type designation |

SPD Selection Decision Guide: Choosing Type 1 vs Type 2 vs Type 3

Follow this systematic Type 1 vs Type 2 vs Type 3 SPD selection approach to choose the right surge protective device for cascade protection systems:

Step 1: Identify Power Supply Configuration for SPD Requirements

- Overhead lines? → Type 1 SPD required at service entrance per NEC 230.67

- Underground cable only? → Type 2 SPD may suffice (verify local code compliance)

- Building has LPS? → Type 1 SPD mandatory per IEC 62305 and IEC 61643-11

Step 2: Assess Equipment Sensitivity for Cascade Protection

- Industrial machinery/HVAC: Type 2 SPD at distribution boards provides adequate surge protection

- IT/telecom/medical: Type 2 + Type 3 SPD cascade protection coordination required

- Standard appliances: Type 2 SPD usually adequate per IEC 61643-11

Step 3: Verify Cascade Distance for Multi-Stage SPD Systems

- Ensure ≥10 meters cable between SPD stages for proper cascade coordination

- If distance insufficient, add decoupling choke or use combined Type 1+2 SPD per IEC 61643-11

Step 4: Check Code Compliance for SPD Installation

- Confirm local adoption of NEC 230.67 (residential SPD mandate)

- Verify SPD carries IEC 61643-11 certification and CE marking

- Ensure installation meets manufacturer specifications for cascade protection

Pro Tip: For maximum surge protection, implement a full three-stage cascade coordination: Type 1 SPD at service entrance → Type 2 SPD at distribution boards → Type 3 SPD at sensitive equipment terminals per IEC 61643-11 best practices.

Real-World SPD Application: Data Center Cascade Protection

Data centers require coordinated Type 1 vs Type 2 vs Type 3 SPD cascade protection to safeguard critical infrastructure. This three-level surge protective device configuration combines Type 1 SPD at service entrance, Type 2 SPD at distribution panels, and Type 3 SPD at equipment terminals against power surges and lightning strikes.

Three-Level Cascade Protection Strategy for Data Centers

Figure 5: Data Center Three-Level SPD Cascade Protection System

Level 1: Service Entrance Protection (Type 1 AC SPD)

- Installation Location: Main distribution board at utility service entrance per NEC 230.67

- Product Selection: Type 1 AC SPD with Iimp ≥50kA (10/350μs)

- Function: Diverts direct lightning strikes and utility-side high-energy surges before reaching facility infrastructure

Level 2: Distribution Panel Protection (Type 2 AC SPD)

- Installation Location: UPS input panels and sub-distribution boards (≥10m from Type 1 SPD)

- Product Selection: Type 2 AC SPD with In=40kA, Imax=80kA (8/20μs)

- Function: Absorbs switching transients from UPS systems in cascade coordination with Type 1 SPD

Level 3: Equipment-Level Protection (Type 3 AC SPD)

- Installation Location: Server rack PDUs, network equipment power strips (≥10m from Type 2 SPD)

- Product Selection: Type 3 AC SPD with Imax=10kA (8/20μs)

- Function: Final voltage limiting at point-of-use, completing cascade protection to Up ≤1.5kV

Network and Signal Line Protection: Data centers also require network and signal SPD solutions including RJ45 Ethernet protectors, RS485 industrial communication SPDs, and coaxial RF surge arresters for comprehensive surge protection.

Protection Results: Properly coordinated cascade SPD systems deliver zero unplanned downtime from surge events, extended UPS and server hardware lifespan, and typical ROI of 12:1 to 20:1 through avoided damage costs. All installations comply with NEC Article 230.67 and IEC 61643-11 standards.

Frequently Asked Questions About Type 1 vs Type 2 vs Type 3 SPD

What is the main difference between Type 1 and Type 2 SPD?

The primary difference between Type 1 and Type 2 SPD lies in their test waveform and installation location per IEC 61643-11:

- Type 1 SPD: Tested with 10/350μs impulse current (Iimp), designed for direct lightning strikes at the service entrance per NEC 230.67.

- Type 2 SPD: Tested with 8/20μs waveform, handles switching transients and indirect lightning at distribution panels.

Installation: Type 1 SPD goes at the main service entrance, while Type 2 SPD installs at secondary distribution boards ≥10 meters downstream.

Energy handling: Type 1 SPD handles 50,000+ joules compared to Type 2 SPD (2,000-15,000 joules).

Do I need Type 1 or Type 2 SPD for underground cable supply?

For buildings with underground cable supply only, a Type 2 SPD is typically sufficient per IEC 61643-11, unless:

Type 1 SPD is required when:

- Building has a lightning protection system with air terminals per IEC 62305

- Overhead power lines exist anywhere in the supply chain

- Facility is in a high-lightning-activity region

Can Type 3 SPD be used alone without Type 2?

No, Type 3 SPD must never be used alone per IEC 61643-11 requirements. It requires upstream Type 2 SPD protection.

Why Type 3 SPD Cannot Stand Alone:

- Low energy capacity: Type 3 SPD can only handle 5-10kA

- Overload risk: Moderate surges will destroy Type 3 SPD without upstream protection

What is the minimum distance between Type 2 and Type 3 SPD in cascade protection?

The minimum recommended cable distance is 10 meters between Type 2 and Type 3 SPD per IEC 61643-11.

Why This Distance Matters:

- Decoupling effect: Cable inductance forces upstream Type 2 SPD to activate first

- Energy sharing: Type 2 SPD absorbs bulk of surge energy

Why is Type 1 SPD more expensive than Type 2?

Type 1 SPD costs 2-4× more than Type 2 SPD due to:

- Larger components: High-energy varistors to handle 10/350μs waveforms

- Specialized testing: 10/350μs impulse testing requires expensive equipment

- Robust construction: Reinforced enclosures for direct lightning protection

How often should SPDs be replaced?

SPD replacement depends on surge activity and visual indicators per IEC 61643-11:

Replace Immediately If:

- Status indicator shows failure (red light, blown fuse)

- Physical damage visible (burn marks, cracked housing)

Typical Service Life:

- Low-surge environments: 10-15 years

- High-surge environments: 3-5 years

What are the official IEC 61643-11 definitions for Type 1, Type 2, and Type 3 SPD?

The official IEC 61643-11 definitions are:

- Type 1 SPD (Class I): Tested with 10/350μs impulse current. Designed for direct lightning strikes at service entrance. Iimp 25-100kA per phase.

- Type 2 SPD (Class II): Tested with 8/20μs impulse current. Designed for switching transients at distribution panels. Rated by In and Imax.

- Type 3 SPD (Class III): Tested with 8/20μs combination wave. Point-of-use protection. Must be downstream of Type 2 SPD.

How do 10/350μs and 8/20μs test waveforms differ in Type 1 vs Type 2 vs Type 3 SPD?

10/350μs waveform (Type 1 SPD):

- 10μs rise time, 350μs decay to 50% of peak

- Simulates direct lightning strike current

- Delivers significantly more energy than 8/20μs

8/20μs waveform (Type 2 & Type 3 SPD):

- 8μs rise time, 20μs decay to 50% of peak

- Simulates switching transients and indirect lightning

- Shorter duration with less total energy

What is the difference between Iimp, In, and Imax current ratings in SPD specifications?

Iimp (Impulse Current) - Type 1 SPD only:

- Maximum 10/350μs current capacity: 25kA to 100kA per phase

- Represents direct lightning strike protection capability

In (Nominal Discharge Current) - Type 2 SPD:

- Rated 8/20μs discharge current: 10-40kA per phase

- SPD can handle this current multiple times without degradation

Imax (Maximum Discharge Current) - Type 2 & Type 3 SPD:

- Maximum single-impulse capacity: Type 2 (20-100kA); Type 3 (5-10kA)

- Represents extreme surge handling before failure

Conclusion: Selecting the Right SPD for Your Electrical System

Making the right Type 1 vs Type 2 vs Type 3 SPD selection requires careful analysis of five key factors for effective cascade protection coordination:

- Power supply configuration: Overhead lines mandate Type 1 SPD per NEC 230.67; underground cables typically allow Type 2 SPD

- Surge energy exposure: Direct lightning requires 10/350μs protection (Type 1); indirect/switching surges need 8/20μs capacity (Type 2/3)

- Equipment sensitivity: Critical electronics benefit from cascaded Type 2 + Type 3 surge protection per IEC 61643-11

- Installation architecture: Maintain ≥10m spacing between SPD stages for proper cascade coordination

- Code compliance: Verify NEC 230.67, IEC 61643-11, and local electrical code requirements for surge protection

Recommended Cascade Protection Strategy:

- Minimum protection: Type 2 SPD at main distribution board (underground supply, low-risk areas) per IEC 61643-11

- Standard protection: Type 1 SPD at service entrance + Type 2 SPD at distribution boards (overhead lines, commercial buildings requiring NEC 230.67 compliance)

- Maximum protection: Complete Type 1 vs Type 2 vs Type 3 SPD cascade coordination (critical facilities, sensitive equipment requiring Up ≤1.5kV)

Properly coordinated Type 1 vs Type 2 vs Type 3 SPD cascade protection not only safeguards expensive equipment but also ensures electrical system reliability, reduces downtime, and maintains compliance with international safety standards including IEC 61643-11 and NEC 230.67.

Standards, Compliance, and Technical Resources for SPD

For detailed Type 1 vs Type 2 vs Type 3 SPD technical specifications and installation guidelines for surge protective device cascade protection, refer to these authoritative sources:

- IEC 61643-11: Low-voltage surge protective devices – Part 11: Surge protective devices connected to low-voltage power systems

- NEC Article 230.67: National Electrical Code (NFPA 70) – Surge Protection for Services

- IEEE C62.41.2: Guide on Surge Environment in Low-Voltage AC Power Circuits

- UL 1449 4th Edition: Standard for Surge Protective Devices

Related Type 1 vs Type 2 vs Type 3 SPD Resources

Explore our comprehensive SPD product guides and technical resources:

- Type 1 SPD Products - Service entrance lightning protection

- Type 2 SPD Installation Requirements - Distribution panel protection guidelines

- AC Surge Protection Solutions - Complete cascade protection systems

- Network & Signal SPD - Data line and communication protection

Need Expert Type 1/Type 2/Type 3 SPD Solutions?

TrilPeak provides comprehensive surge protection design consultation and IEC 61643-11 compliant SPD products with CE certification. Contact our technical team for customized cascade protection solutions.

Get Free SPD Consultation →