- Home

- »

- Type 1+2 surge protective device

Type 1+2 Surge Protection Device (SPD) – Combined Lightning & Switching Surge Protection

Type 1+2 surge protection device (also known as Type 1+2 SPD or combined surge protector) provides comprehensive protection against both direct lightning strikes (Type 1) and switching surges (Type 2) in a single compact unit. Tested to IEC 61643-11:2025 standards, it simplifies installation, reduces costs, and saves panel space compared to separate Type 1 + Type 2 solutions.

✅ 2-in-1 Design | ✅ Space Saving | ✅ Cost Effective | ✅ IEC 61643-11:2025 Compliant

What is Type 1+2 Surge Protection Device?

A Type 1+2 Surge Protection Device (SPD) combines lightning impulse protection (Type 1) and switching surge protection (Type 2) into a single integrated unit. Certified to IEC 61643-11:2025, it handles both direct lightning strikes (10/350 µs waveform, 7-25kA Iimp) and induced surges (8/20 µs waveform, 25-60kA In), eliminating the need for separate devices.

Key benefits include simplified installation, reduced panel space, and lower system costs. Ideal for industrial facilities, commercial buildings, data centers, and critical infrastructure requiring robust protection with voltage protection levels (Up) from 1.4kV to 2.5kV.

TPK-7 SERIES

7kA Type 1+2 SPD

Compact pluggable Type 1+2 SPD for secondary distribution panels. Combines 7kA lightning impulse current discharge (10/350µs) with 25kA nominal discharge capacity (8/20µs) for reliable protection. IEC 61643-11 Class I+II certified.

Iimp (10/350µs)

7 kA

In (8/20µs)

25 kA

Imax (8/20µs)

50 kA

Uc

275V / 320V / 385V / 420V

Up

≤ 1.4kV / 1.6kV / 1.8kV / 2.0kV

🏢 Commercial & Office Buildings

- Pluggable format for easy replacement

- Biconnect dual terminal design

- Green/Red mechanical status indicator

- 1P+N / 3P / 3P+N / 4P configurations

- PLC network compatible

- Optional remote signaling

TPK-12.5 SERIES

12.5kA Type 1+2 SPD

Enhanced pluggable Type 1+2 SPD with increased energy handling capacity. 12.5kA lightning impulse capability (10/350µs) with 30kA nominal discharge (8/20µs) for demanding industrial applications. Features hot-swap modular design.

Iimp (10/350µs)

12.5 kA

In (8/20µs)

30 kA

Imax (8/20µs)

60 kA

Uc

275V / 320V / 385V / 420V

Up

≤ 1.4kV / 1.6kV / 1.8kV / 2.0kV

🏭 Industrial & Data Centers

- 60kA maximum discharge capacity

- Hot-swap pluggable format

- Thermal overload protection

- Biconnect dual terminal technology

- IEC 61643-11:2025 certified

- Suitable for moderate lightning exposure

TPK-I-15 SERIES

15kA Type 1+2 SPD

Heavy-duty monobloc Type 1+2 SPD for incoming supply panels. 15kA lightning impulse current (10/350µs) with exceptional 120kA maximum discharge capacity (8/20µs) for high-exposure installations with external lightning protection systems.

Iimp (10/350µs)

15 kA

In (8/20µs)

60 kA

Imax (8/20µs)

120 kA

Uc

275V / 320V / 385V / 420V

Up

≤ 2.0kV / 2.2kV / 2.5kV / 2.5kV

🏗️ Main Panels & High-Rise Buildings

- Monobloc robust construction

- 120kA extreme discharge capability

- Fire-resistant PA66 UL94 V-0 housing

- Red mechanical failure indicator

- Designed for LPS coordination

- 3P / 3P+N / 4P configurations

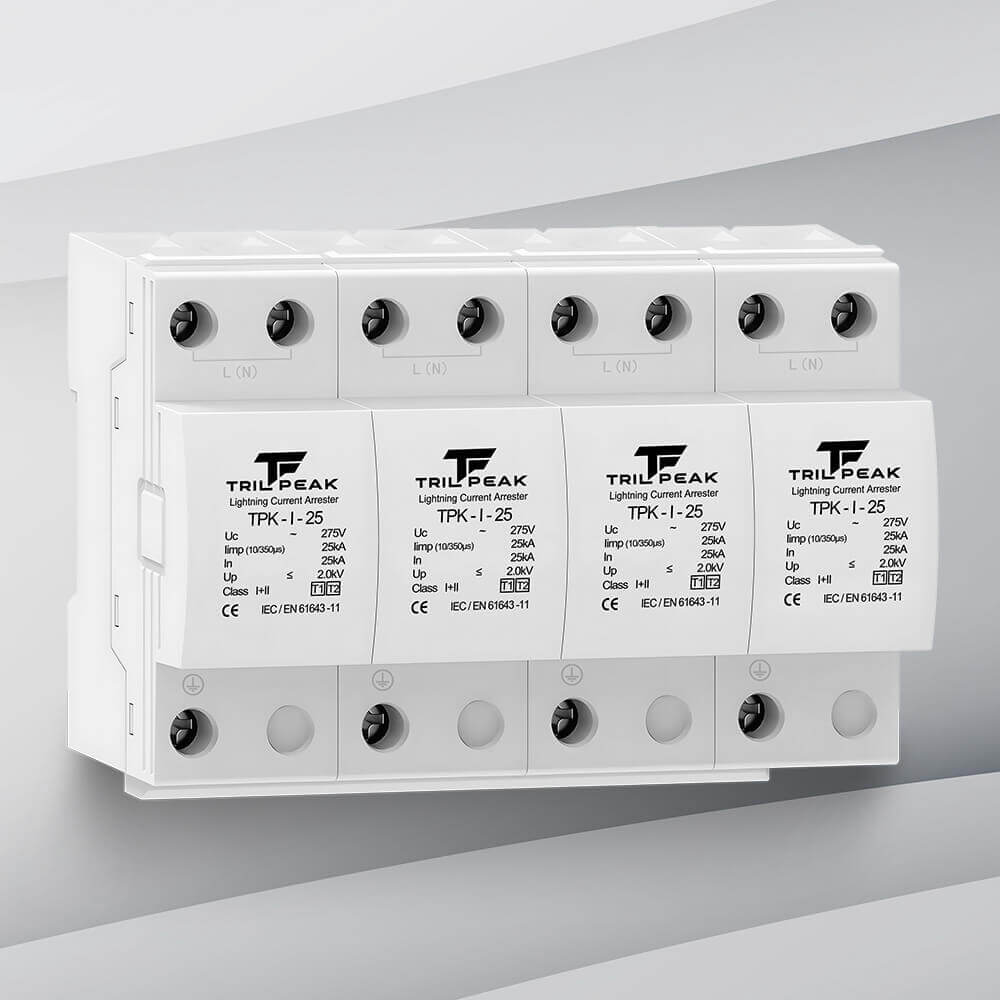

TPK-I-25 SERIES

25kA Type 1+2 SPD

Premium monobloc Type 1+2 SPD with maximum lightning protection. 25kA lightning impulse capacity (10/350µs) designed for direct strike energy discharge in extreme lightning risk areas. Suitable for critical infrastructure and power stations.

Iimp (10/350µs)

25 kA per phase

In (8/20µs)

25 kA

Uc

255V

Up

≤ 2.0kV (TNC/TNS) / ≤ 1.5kV (TT)

Max Backup Fuse

315A gL

⚡ Critical Infrastructure & Power Stations

- 25kA highest lightning impulse rating

- Direct strike energy capability

- Universal earthing compatibility (TT/TNS/TNC/IT)

- Monobloc reinforced construction

- 315A maximum backup fuse protection

- Extreme lightning risk area design

Complete Your Lightning Protection System

Type 1+2 SPDs Are Just One Component – Build a Multi-Layer Defense

Type 1+2 SPDs protect your distribution panels, but a comprehensive lightning protection strategy requires multiple defense layers. Maximize equipment uptime, prevent costly damage, and ensure compliance with IEC 62305 standards by integrating these essential components:

Three Phase SPD

Protect your three-phase distribution system. Most industrial and commercial facilities operate on three-phase power (380V/400V or 480V). Type 1+2 SPDs protect the main panel, but three-phase systems require coordinated protection at sub-distribution boards and critical equipment branches to ensure complete coverage.

Why You Need It:

• 85% of Type 1+2 customers operate three-phase systems

• Extends main panel protection to sub-distribution boards

• Essential for industrial, commercial, and data center facilities

• Coordinates with Type 1+2 for comprehensive power line protection

Type 3 SPD (Class III)

Protect sensitive equipment at the point of use. Type 1+2 SPDs protect at the main distribution panel, but residual surge energy can still reach sensitive electronics through long cable runs. Type 3 SPDs are installed directly at terminal devices to provide the final layer of protection for computers, PLCs, medical equipment, and precision instruments.

Why You Need It:

• Required for circuits longer than 10 meters from Type 1+2

• Prevents equipment malfunction, data loss, and downtime

• Essential for IT, medical, automation, and lab equipment

• Coordinates with Type 1+2 for complete cascade protection

Signal Line SPD

Protect data, network, and communication lines. Lightning surges don't only travel through power lines—data cables, phone lines, and network connections are equally vulnerable. Signal Line SPDs protect Ethernet networks, RS485 industrial buses, telephone systems, and coaxial connections from surge damage that can destroy network equipment and cause costly communication downtime.

Why You Need It:

• Data centers and network infrastructure require signal line protection

• Industrial control systems use RS485/RS232 communication buses

• Prevents network equipment damage and communication downtime

• Essential for facilities with outdoor cables or long cable runs

Type 1+2 Surge Protection Device: Combined Lightning & Surge Protection

Industrial-grade surge protective devices for main distribution panels – IEC 61643–11 certified lightning impulse protection and switching surge protection in a single unit. Our Type 1+2 SPDs combine 10/350μs direct lightning strike protection (Class I tested, 7–25 kA Iimp) with 8/20μs switching surge protection (Class II tested, 25–60 kA In) in a single device, replacing separate SPDs to save panel space and labor cost. Ideal for industrial facilities, commercial buildings, data centers, hospitals & healthcare, telecom infrastructure, and critical infrastructure.

Why You Need Type 1+2 Surge Protection Device?

Type 1+2 SPD combines two critical protection levels in one device, eliminating the need for separate Type 1 and Type 2 surge protectors at your main distribution panel. This integrated solution delivers comprehensive lightning and switching surge protection while reducing installation complexity, saving panel space, and lowering total system costs. Understanding the advantages of combined Type 1+2 protection helps you make informed decisions for your facility‘s electrical safety infrastructure.

The Lightning Surge Protection Challenge

Traditional surge protection approaches using separate Type 1 and Type 2 devices create four significant operational challenges:

- Crowded Panels – Two separate devices consume 6-12 DIN rail modules in already-packed distribution panels, limiting space for other critical components and forcing costly enclosure expansions.

- Double Labor Time – Installing two devices doubles wiring complexity and extends installation time from 30-45 minutes to 60-90 minutes, increasing labor costs by 40-50%.

- Coordination Challenges – Separate Type 1 and Type 2 devices require careful matching of voltage protection levels, discharge currents, and response characteristics to ensure proper cascade operation without device failure or premature clamping.

- More Maintenance – Two devices mean double the monitoring points, service schedules, replacement intervals, and failure tracking—increasing maintenance workload and operational complexity throughout the system lifecycle.

Type 1+2 SPD: The All-in-One Solution

Dual-Layer Protection in One Unit

Type 1+2 SPD is tested to both 10/350 µs (Class I) and 8/20 µs (Class II) waveforms, providing comprehensive protection against direct lightning strikes and induced switching surges in a single device. No need for separate coordination—it's factory-engineered to handle both threats.

Space-Saving Design

Replaces two separate devices with one compact unit. A typical Type 1+2 SPD occupies 3-8 DIN rail modules, compared to 6-12 modules for separate Type 1 and Type 2 devices. Critical in crowded distribution panels where every module counts.

Simplified Installation & Lower Cost

One device means faster installation, less wiring, and reduced labor costs. Electricians only need to wire one SPD instead of two, cutting installation time by 40-50%. Lower upfront cost compared to purchasing Type 1 and Type 2 separately.

IEC 61643-11:2025 Certified Performance

Type 1+2 SPDs are rigorously tested to the latest IEC 61643-11:2025 standard, ensuring they can withstand both lightning impulse currents (Iimp 7-25 kA per phase) and maximum discharge currents (In 25-60 kA). Factory-verified performance eliminates guesswork.

Type 1+2 Surge Protection Device vs. Separate Type 1 + Type 2 Comparison

Direct comparison reveals clear advantages of the combined approach. Type 1+2 SPDs require only 3–8 DIN rail modules versus 6–12 for separate devices, install in 30–45 minutes versus 60–90 minutes, and feature simple single-device wiring versus complex dual-device coordination. While both approaches provide equivalent 10/350 µs and 8/20 µs protection coverage, Type 1+2 offers lower total cost (single device purchase and reduced labor) and simplified maintenance through single-point monitoring instead of managing two separate protection points.

Type 1+2 Surge Protection Device offers significant advantages over traditional separate installations. The following comparison demonstrates why combined protection is the preferred solution for modern electrical systems.

| Feature | Type 1+2 Combined | Separate Type 1 + Type 2 |

|---|---|---|

| Installation Time | 30-45 minutes | 60-90 minutes |

| Number of Devices | 1 device | 2 devices |

| Wiring Complexity | Simple | Complex (coordination required) |

| Panel Space | Compact (single unit) | Larger footprint (2 units) |

| Protection Coverage | 10/350 µs + 8/20 µs | 10/350 µs + 8/20 µs |

| Total System Cost | Lower | Higher (device + labor) |

| Maintenance | Single-point monitoring | Dual-point monitoring |

| Standards Compliance | IEC 61643-11:2025 | IEC 61643-11:2025 |

As shown above, Type 1+2 Surge Protection Device provides superior value through integrated design, reduced installation time, and lower total cost of ownership.

When to Choose Type 1+2 SPD

Install Type 1+2 combined surge protectors at your facility's main distribution panel to protect against both direct lightning strikes (10/350 µs) and switching surges (8/20 µs) in a single device. Ideal for industrial facilities, commercial buildings, and data centers requiring IEC 61643-11 compliant protection without consuming excessive DIN rail space or doubling installation labor costs.

Buildings equipped with external air termination systems and down conductors require Type 1 surge protection at the service entrance per IEC 62305-3 standards. Type 1+2 SPD provides mandatory Class I lightning impulse protection (Iimp 7-25 kA) while simultaneously handling induced switching surges—eliminating the need for separate coordination between Type 1 and Type 2 devices in high lightning exposure regions.

Overcome limited DIN rail space in existing electrical distribution panels by replacing two separate devices with one compact Type 1+2 SPD. Typical installations save 3-6 DIN modules compared to dual-device setups—critical for retrofit projects, panel upgrades, and space-constrained installations where expanding enclosures is cost-prohibitive. Reduce installation time by 40-50% and simplify maintenance with single-point monitoring.

Reduce total system cost through combined device purchase savings and 40-50% lower installation labor compared to separate Type 1 and Type 2 SPDs. Single-device architecture minimizes maintenance burden with one monitoring point, one replacement schedule, and simplified lifecycle management. Ideal for budget-conscious projects, facility managers prioritizing operational efficiency, and organizations seeking long-term reliability without recurring dual-device coordination costs.

Find Your Perfect Type 1+2 Surge Protection Device Solution

Type 1+2 SPD delivers comprehensive lightning and switching surge protection in a single device—saving panel space, reducing installation costs by 40-50%, and simplifying maintenance throughout your system‘s lifecycle. Our technical team can assess your facility’s lightning exposure, panel configuration, and protection requirements to recommend the optimal Type 1+2 SPD solution.

How Type 1+2 SPD Protects Power Systems?

When lightning strikes your facility, surge currents up to 200 kA enter through power lines. Type 1+2 SPD installed at the main distribution panel detects overvoltage within nanoseconds and activates spark gap or gas discharge tube components to intercept high-energy 10/350 µs impulse currents before they reach downstream equipment.

The Type 1 component safely diverts lightning impulse currents (Iimp 7-25 kA per phase) to ground using spark gap technology designed for 10/350 µs waveforms. This protects your main circuit breakers, transformers, and distribution equipment from catastrophic damage caused by direct lightning strikes, meeting IEC 61643-11 Class I requirements.

After primary lightning discharge, residual surge energy and switching transients from inductive loads or motor startups still threaten equipment. The Type 2 component uses metal oxide varistors to clamp 8/20 µs waveform surges, limiting voltage to Up ≤ 1.4-2.5 kV with maximum discharge current ratings of 25-60 kA.

Type 1+2 SPD at the service entrance coordinates with downstream Type 3 SPDs to create a cascaded protection system. By reducing surge energy at the main panel, downstream devices experience only low-residual voltage stress—extending equipment lifespan, preventing nuisance tripping, and maintaining system uptime for critical loads.

Industrial Type 1+2 Surge Protection Device Applications

Type 1+2 combined surge protection devices provide comprehensive lightning and switching surge protection across critical industries. From industrial facilities to healthcare, these IEC 61643-11 certified devices protect main distribution panels, sensitive equipment, and critical infrastructure.

Why Choose Trilpeak Type 1+2 SPD Manufacturer?

Trilpeak is a leading industrial surge protection type 1+2 manufacturer with 25 years of expertise producing IEC 61643-11 certified devices in our 12,000 m² ISO 9001:2015 facility. We solve your surge protection device type 1+2 procurement challenges by offering factory-direct pricing on combined type 1+2 spd products, eliminating distributor markups while maintaining <0.1% defect rates with 10-year warranties. Our comprehensive services include expert type 1+2 spd installation guidance, custom type 1+2 spd specifications design, and flexible OEM/ODM solutions for commercial spd type 1+2 applications—backed by 24/7 multilingual technical support and global shipping to 50+ countries.

Type 1+2 Surge Protective Device FAQ

Expert answers to the most common questions about combined Type 1+2 SPD installation, selection, specifications, and troubleshooting.

What is the difference between Type 1, Type 2, and combined Type 1+2 SPD?

Type 1 SPD is designed to withstand direct lightning strikes using the 10/350µs test waveform (characterized by Iimp rating). It installs at the service entrance where external lightning protection systems are present.

Type 2 SPD handles induced surges and switching transients using the 8/20µs test waveform (characterized by In rating). It installs at distribution boards throughout the facility.

Type 1+2 Surge Protective Device combines both protection levels in a single unit, tested to both waveforms. This eliminates coordination distance requirements and saves panel space while providing comprehensive lightning and surge protection per IEC 61643-11 standards.

When should I install a combined SPD at service entrance?

Type 1+2 Surge Protective Device is mandatory when:

- Building has external lightning rod system (air termination network)

- High lightning exposure areas (tropical regions, hilltops, exposed locations)

- Overhead power line service entrance

- Critical infrastructure requiring maximum protection (data centers, hospitals, industrial facilities)

- Limited panel space where separate installations are not feasible

Benefits of combined surge protection: Eliminates 10-meter coordination distance requirement, reduces installation labor by 40-50%, and provides comprehensive protection tested to both IEC 61643-11 Class I and Class II standards.

How do I select the correct Uc voltage rating for 400V systems?

The correct Uc (Maximum Continuous Operating Voltage) for your Type 1+2 SPD depends on system grounding type:

- TN-S or TN-C-S systems: Uc ≥ 275V (L-N) or 440V (L-L)

- TT systems: Uc ≥ 320V (L-N) or 550V (L-L)

- IT systems: Uc ≥ 440V (L-L), no phase-to-ground protection needed

Why TT systems need higher Uc: During ground faults, TT system voltages can temporarily rise above nominal by 45% or more. Using a standard 275V surge protective device in a TT system will cause premature failure.

Common mistake: Using single Uc rating for all system types. Higher Uc typically means higher Up (protection level), reducing effectiveness.

What backup protection is required per IEC 61643-11?

YES, backup protection is mandatory per IEC 61643-11 Clause 8.3.2.3. Type 1+2 Surge Protective Device units do NOT limit fault current. When the device fails short-circuit due to severe surge damage, the resulting fault current can cause catastrophic damage without proper backup protection.

Standard backup protection options:

- gG Fuse: 100-160A for combined Type 1+2 SPD (IEC 60269 standard)

- MCB (Miniature Circuit Breaker): C40-C63 rating, verify compatibility in datasheet

- Dedicated external protection: For high short-circuit current sites (Isc > 50kA)

Important: The backup protection rating must match the manufacturer's datasheet specification. Never exceed the specified maximum backup fuse or MCB rating.

Does combined protection eliminate coordination distance requirements?

YES, Type 1+2 Surge Protective Device eliminates coordination distance requirements between Type 1 and Type 2 protection stages since both functions are integrated in a single device.

Traditional separate configuration requires: Minimum 10 meters cable length between Type 1 and Type 2 SPDs per IEC 61643-12. If cable distance is less than 10m, a 10-20µH decoupling inductor must be installed.

Combined device advantage: Internal coordination is pre-engineered by the manufacturer, eliminating installer concerns about:

- Measuring and maintaining 10-meter cable separation

- Installing decoupling inductors for compact panel layouts

- Risk of Type 2 conducting first and becoming overloaded

- Complex energy cascade calculations

Note: You still need proper coordination between the service entrance Type 1+2 SPD and downstream Type 2 units at sub-panels.

What is the maximum connection lead length for surge protection installation?

Maximum 0.5 meters total (phase plus ground conductors combined) to minimize inductive voltage drop during surge events.

The physics behind this requirement: At surge frequencies (approximately 1 MHz), each meter of wire has approximately 1µH inductance. During a 20kA surge with 1µs rise time, a 2-meter lead adds approximately 2kV voltage drop, completely negating the Type 1+2 Surge Protective Device protection level (Up).

Installation best practices:

- Mount device immediately adjacent to main busbars

- Use short, straight conductor routing (no coiling for aesthetics)

- Avoid lengthy cable tray routing

- Connect ground terminal directly to main grounding busbar with minimum lead length

Common mistake: SPD mounted at panel bottom with 2m leads routed neatly to top busbar. This looks professional but provides almost no surge protection due to excessive lead inductance.

What is the typical service life and replacement schedule?

Expected service life for Type 1+2 Surge Protective Device:

- Combined units: 10-15 years in typical industrial environments with proper maintenance

- High-exposure applications: 8-12 years in tropical regions or areas with frequent lightning activity

- Low-exposure applications: 12-15 years in urban environments with underground power supply

Inspection schedule:

- Quarterly: Visual check of status indicators, physical damage, overheating signs

- Annually: Detailed inspection including connection torque check, corrosion assessment, remote contact testing

- After lightning storms: Immediate inspection following nearby strikes or severe weather events

Immediate replacement required when: Status indicator shows red or failed condition, visible damage to housing or terminals, after confirmed direct lightning strike, or remote monitoring contact indicates fault.

What technical specifications should I verify when selecting Type 1+2 SPD?

Critical specifications for Type 1+2 Surge Protective Device selection:

- Iimp (Impulse Current): Minimum 12.5 kA (10/350µs) for Type 1 function; 25 kA recommended for high-lightning areas

- Imax (Maximum Discharge Current): Minimum 50 kA (8/20µs) for residential; 100 kA for commercial and industrial applications

- Un (Nominal Voltage): Must match system voltage—230V/400V for TN systems

- Up (Voltage Protection Level): Should be ≤1.5 kV for optimal equipment protection; lower Up equals better protection

- MCOV (Maximum Continuous Operating Voltage): Must exceed normal system voltage variations by 15% minimum

- Short-circuit withstand rating: Verify SCCR matches or exceeds installation point available fault current

Example specification for 400V industrial facility: Combined device with Un=400V (3P+N), Iimp=25kA (10/350µs), Imax=100kA (8/20µs), Up≤1.5kV, MCOV≥460V, SCCR=50kA.

How does installation differ in TN-S versus TT grounding systems?

TN-S System installation:

- Install 3-pole plus neutral (3P+N) configuration

- Connect phase conductors (L1, L2, L3) and neutral (N) to input terminals

- Bond ground terminal to main earthing terminal (MET) via PE conductor

- Select Uc ≥ 275V (L-N) or 440V (L-L) for Type 1+2 Surge Protective Device

TT System installation:

- Install 3-pole plus neutral (3P+N), same as TN-S configuration

- Critical difference: Select higher Uc rating—minimum 320V (L-N) or 550V (L-L)

- Connect ground terminal to installation earth electrode (separate from utility neutral earth)

- TT systems experience higher temporary overvoltages during ground faults, requiring higher MCOV rating

Key technical difference: TT systems can experience neutral-to-earth voltage rise of 200V or more during ground faults. Standard 275V device rated for TN-S will fail prematurely in TT installations. Always specify TT-rated Type 1+2 SPD with Uc ≥ 320V for these applications.

What grounding conductor size is required per IEC standards?

Minimum grounding conductor sizes per IEC 61643-11:

- Type 1 function (10/350µs capability): Minimum 6 AWG (10 mm²) copper conductor

- Type 2 function only (8/20µs): Minimum 10 AWG (6 mm²) copper conductor acceptable

- High Iimp ratings (25 kA or greater): Recommend 4 AWG (16 mm²) copper for Type 1+2 Surge Protective Device

Installation best practices:

- Use compression lugs or bolted connections—never rely on push-in terminals

- Connect ground terminal directly to main grounding electrode system via shortest possible route

- Avoid sharp bends in ground conductor—minimum bend radius of 8 inches (200mm)

- Bond all metal enclosures to prevent side-flash hazards from surge discharge

- For TT systems, connect ground to installation earth electrode, separate from utility neutral earth

Common mistake: Using same 12 AWG ground conductor for combined units as used for standard Type 2 SPDs. The higher energy capacity requires larger conductor to safely carry 10/350µs lightning current to ground.

Can combined SPD be used in solar PV system DC applications?

YES, but you must use DC-rated Type 1+2 Surge Protective Device specifically designed for photovoltaic applications. Standard AC units cannot safely interrupt DC arc fault current and will fail catastrophically if used in DC circuits.

For solar PV DC side protection:

- Voltage rating: DC-rated device Un must exceed 1.2 times PV array open-circuit voltage (Voc). Example: 1000V PV system requires Un ≥ 1200V DC

- Installation location: Install in PV combiner box or DC disconnect enclosure between array and inverter input

- Polarity protection: PV systems require protection of both positive and negative DC conductors to ground. Use 2-pole plus ground configuration

- Arc extinction: Verify DC-rated unit includes proper arc extinction chambers rated for maximum system Voc

For solar PV AC side protection:

- Install standard AC-rated Type 1+2 SPD at inverter AC output panel

- Install second AC unit at main service entrance panel for comprehensive facility protection

- Select Un to match grid voltage (230V/400V typical)

Critical safety note: Never use AC-rated surge protective device on DC circuits. DC arc faults do not have natural current zero-crossing like AC, preventing proper arc extinction. This can result in sustained arcing, fire, and device explosion.

How do I test and verify proper functioning?

Testing methods for Type 1+2 Surge Protective Device:

Visual inspection (quarterly):

- Check status indicator LED (green indicates operational, red or off indicates fault)

- Inspect housing for discoloration, cracks, or bulging

- Verify no visible corrosion on terminals

- Feel enclosure—should be ambient temperature (warm indicates internal failure)

Electrical testing (annually):

- Insulation resistance test: Disconnect device from circuit. Use megohmmeter to measure L-G and N-G resistance. Should read greater than 1 MΩ. Low resistance indicates degradation

- Voltage measurement: Measure L-N and L-G voltages at terminals. Abnormal readings (greater than 5V difference) indicate device conducting

- Remote contact verification: Test alarm contact function using multimeter continuity check

Advanced testing:

- Thermal imaging: Use IR camera to scan during operation. Hot spots indicate internal varistor failure or poor connections

- Leakage current measurement: Measure steady-state current through device. Should be less than 1mA. Higher leakage indicates nearing end of life

Important safety note: Never attempt to open or repair the unit. Internal varistors may retain residual charge. Always replace entire device per manufacturer instructions when fault is detected.

What configuration is recommended for industrial facilities?

Comprehensive industrial surge protection strategy:

Primary protection—Main service entrance:

- Install Type 1+2 Surge Protective Device (Iimp ≥25 kA, Imax ≥100 kA) at primary switchgear incoming section

- Select combined unit with remote monitoring contacts for integration with facility monitoring system

- Specify 4-pole configuration (3P+N) for TN-S systems or 3-pole plus ground for TT systems

- Verify short-circuit withstand rating matches main service fault current level

Secondary protection—Distribution level:

- Install Type 2 SPD (Imax ≥40 kA) at each motor control center (MCC) and distribution board

- Maintain minimum 10 meters cable distance between service entrance and distribution units

- If cable distance is less than 10m, install 15µH decoupling inductor before Type 2 device

Tertiary protection—Critical equipment:

- Install Type 3 SPD at sensitive loads (PLCs, VFDs, control systems, instrumentation)

- Coordinate Up rating to be lower than upstream protection levels

Monitoring integration:

- Connect all alarm contacts to facility SCADA or building management system (BMS)

- Configure alert notifications for end-of-life conditions

- Log surge events for predictive maintenance planning

Is combined protection more cost-effective than separate installations?

YES, Type 1+2 Surge Protective Device offers significant cost advantages:

Equipment cost savings:

- Combined unit typically 20-30% less expensive than purchasing separate Type 1 plus Type 2 devices

- Eliminates decoupling inductor (saves 150-200 USD per installation)

- Reduced enclosure size requirements, lowering material costs

Installation labor savings:

- Single installation saves 40-50% labor hours versus two separate installations

- Simplified wiring—one set of phase, neutral, and ground connections instead of two

- No coordination distance measurement required

- Single backup protection device instead of two separate units

Operational cost savings:

- Saves 50% panel real estate—critical in retrofit applications with limited space

- Simplified maintenance—single unit to inspect and monitor instead of two

- Reduced spare parts inventory—stock one model instead of separate units

Example total cost comparison for 400V commercial facility:

- Combined solution: 350 USD device plus 100 USD installation labor equals 450 USD total

- Separate solution: 250 USD Type 1 plus 180 USD Type 2 plus 200 USD decoupling inductor plus 180 USD installation labor equals 810 USD total

- Cost savings: 360 USD per installation point (44% reduction)

Does Type 1+2 Surge Protective Device comply with IEC 61643-11 and UL 1449 standards?

YES, combined devices must comply with both international and regional standards:

IEC 61643-11 requirements:

- Class I testing (Type 1 function): Must pass 10/350µs impulse current test at rated Iimp level (typically 12.5 kA or 25 kA per pole)

- Class II testing (Type 2 function): Same device must pass 8/20µs discharge current test at rated Imax level (typically 40-100 kA)

- Thermal stability test: Must operate continuously at maximum continuous operating voltage (MCOV) without thermal runaway

- Short-circuit withstand: Must safely disconnect under maximum expected short-circuit current (SCCR rating)

- Endurance testing: Must withstand 15 impulses at nominal discharge current without degradation

UL 1449 4th Edition requirements for North America:

- Type 1 designation: Must be listed for installation on line side of service entrance main overcurrent protection device

- Voltage protection rating (VPR): Tested at multiple current levels (3 kA, 5 kA, 10 kA) per UL 1449 procedure

- Abnormal overvoltage test: Must safely fail when subjected to temporary overvoltage (TOV) conditions

- Short-circuit current rating (SCCR): Must withstand and safely disconnect under available fault current at installation point

How to verify compliance:

- Check for IEC 61643-11 test report from accredited laboratory (KEMA, CESI, UL, TÜV) documenting both Class I and Class II test results

- Verify UL 1449 listing mark on nameplate for North American installations

- Request manufacturer's declaration of conformity documenting compliance with all applicable standards

Warning: Some manufacturers market "Type 1+2" units that only meet Type 2 testing requirements (8/20µs) with inflated current ratings. True Type 1+2 Surge Protective Device must have documented test reports for both 10/350µs (Class I) and 8/20µs (Class II) waveforms per IEC 61643-11 standard.